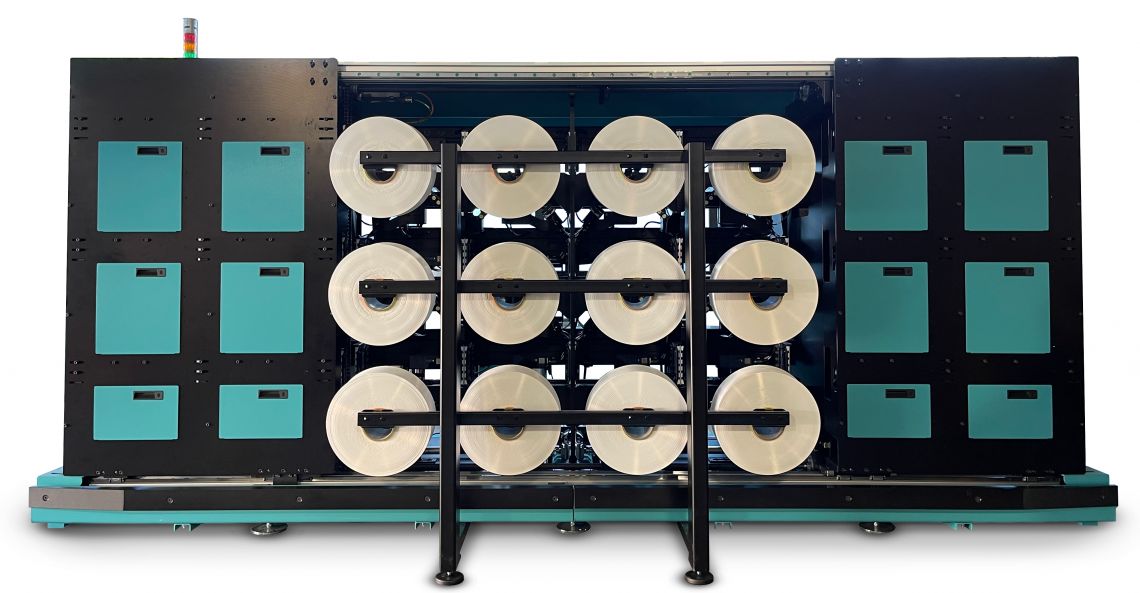

RA VISION 24 & 32

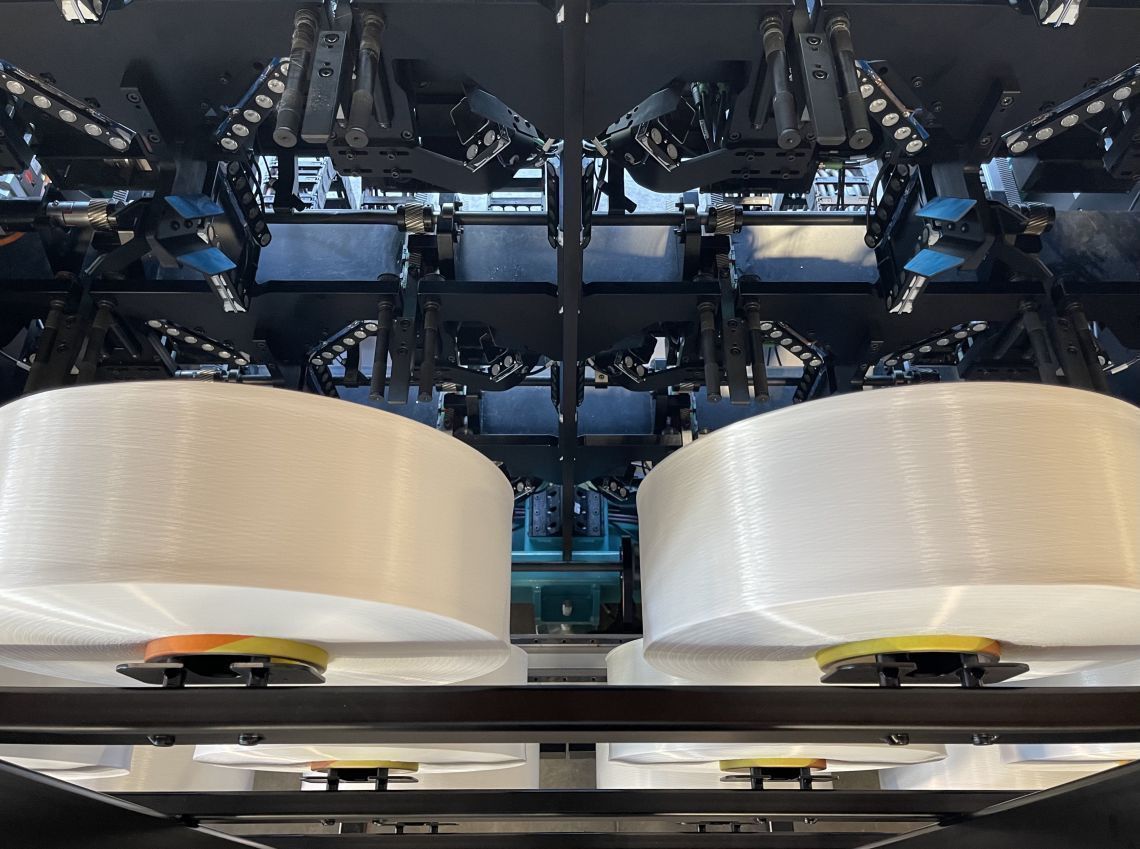

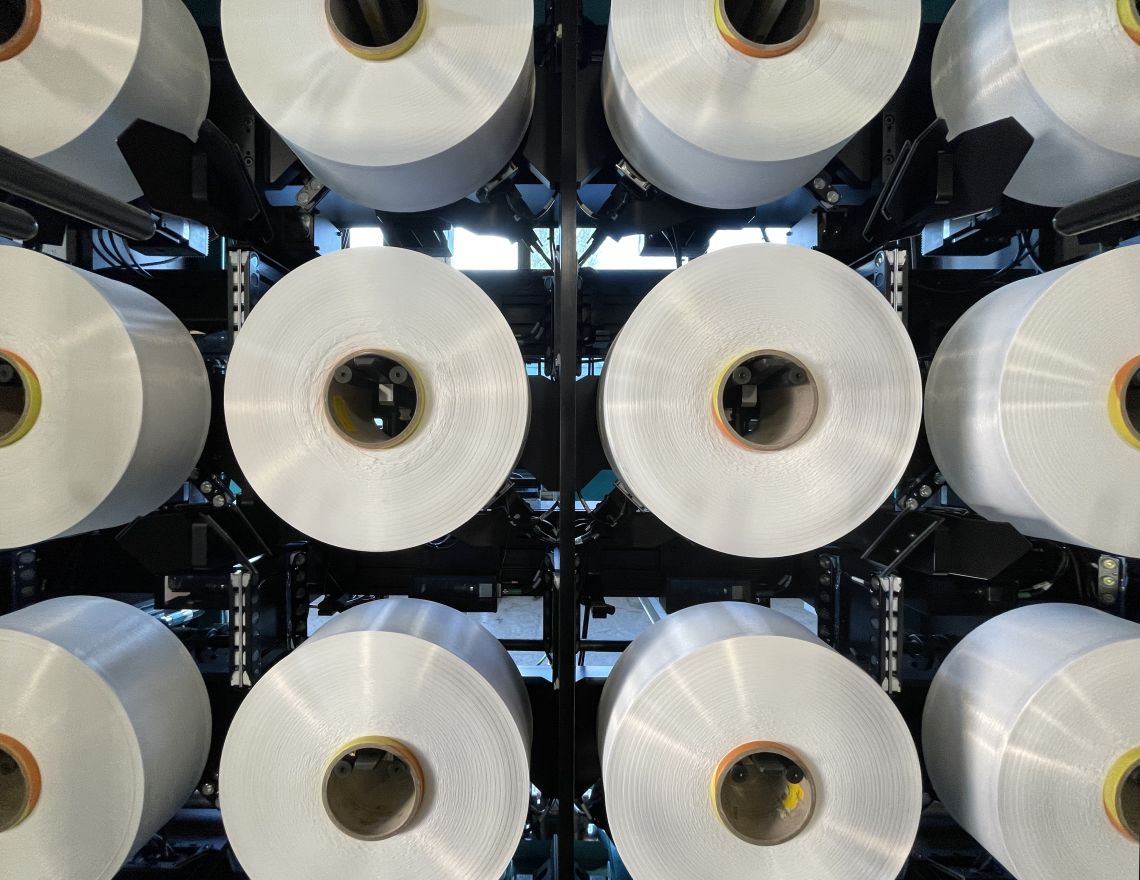

Ra Vision is a tool for visual inspection of POY, FOY, FDY and DTY yarn bobbins produced in a spinning and texturing process, to identify possible problems and defects such as:

- Broken filaments - very short (visible up to minimum 2 mm)

- Broken filaments - medium/long

- Dropped ends fallen on the bobbin sides

- Concentration of small hairs (fluffs-micro-breaks) on the bobbin surface

- Buttonholes

- Correct bobbin profile

- Bobbin sides with concave or convex profile

- Check the bobbin outer edges

- Check the first centimeter of yarns in contact with the tube

- Check if there are grooves on the bobbin sides

- Check the presence of the transfer tail

- Double transfer tail

- Transfer tail too short

- Transfer tail interrupted

- Dirt stains on the bobbin

- Oil stains on the bobbin

- Changes of color shade of the bobbin

Ra Vision, in its various versions, can be used in an automated bobbins transport system, both on trolleys / shuttles with aerial guides and on systems with conveyor belt.

The versions for trolleys / shuttles take on average up to 32 seconds to display and analyse 24 or 32 bobbins simultaneously and with extreme precision.

The obtained results will be available in real time for the company DB and for the following warehouse or packaging processes.

The versions and dimensions of Ra Vision are reviewed each time and calculated according to the production to be checked over the daily 24 working hours and the existing conditions and automatisms.

- Broken filaments - very short (visible up to minimum 2 mm)

- Broken filaments - medium/long

- Dropped ends fallen on the bobbin sides

- Concentration of small hairs (fluffs-micro-breaks) on the bobbin surface

- Buttonholes

- Correct bobbin profile

- Bobbin sides with concave or convex profile

- Check the bobbin outer edges

- Check the first centimeter of yarns in contact with the tube

- Check if there are grooves on the bobbin sides

- Check the presence of the transfer tail

- Double transfer tail

- Transfer tail too short

- Transfer tail interrupted

- Dirt stains on the bobbin

- Oil stains on the bobbin

- Changes of color shade of the bobbin

Ra Vision, in its various versions, can be used in an automated bobbins transport system, both on trolleys / shuttles with aerial guides and on systems with conveyor belt.

The versions for trolleys / shuttles take on average up to 32 seconds to display and analyse 24 or 32 bobbins simultaneously and with extreme precision.

The obtained results will be available in real time for the company DB and for the following warehouse or packaging processes.

The versions and dimensions of Ra Vision are reviewed each time and calculated according to the production to be checked over the daily 24 working hours and the existing conditions and automatisms.